The 16th edition of the biennial Auto Components Machinery and Engineering Equipment (ACMEE) event, hosted by the Ambattur Industrial Estate Manufacturers Association (AIMEA) at the Chennai Trade Centre, took place from June 19 to June 23, bringing together automation and robotics. It exhibited smart manufacturing of tools propelled by AI and digital manufacturing.

The event proved to be a watershed moment for India’s tool manufacturing industry, which is dubbed the “frugal engineering capital of the world” for achieving more with less. Inaugurated by the Chief Minister of Tamil Nadu, MK Stalin, the event exhibits the promotion of the Make in India initiative through cutting-edge machine tool technology.

Participants included some of India’s oldest machine tool manufacturers, foreign subsidiaries based in India, foreign participants and home-grown players. Over 470 exhibitors from Germany, Taiwan, Japan and other countries participated, showcasing their innovations in automation, robotics, precision tools, metallurgy and engineering components.

This year’s attraction was intelligent automation with over 150 stalls dedicated to robotics, AI and digital manufacturing. The components focused on enabling the country’s manufacturing sector to gear up for the Industry 4.0 leap.

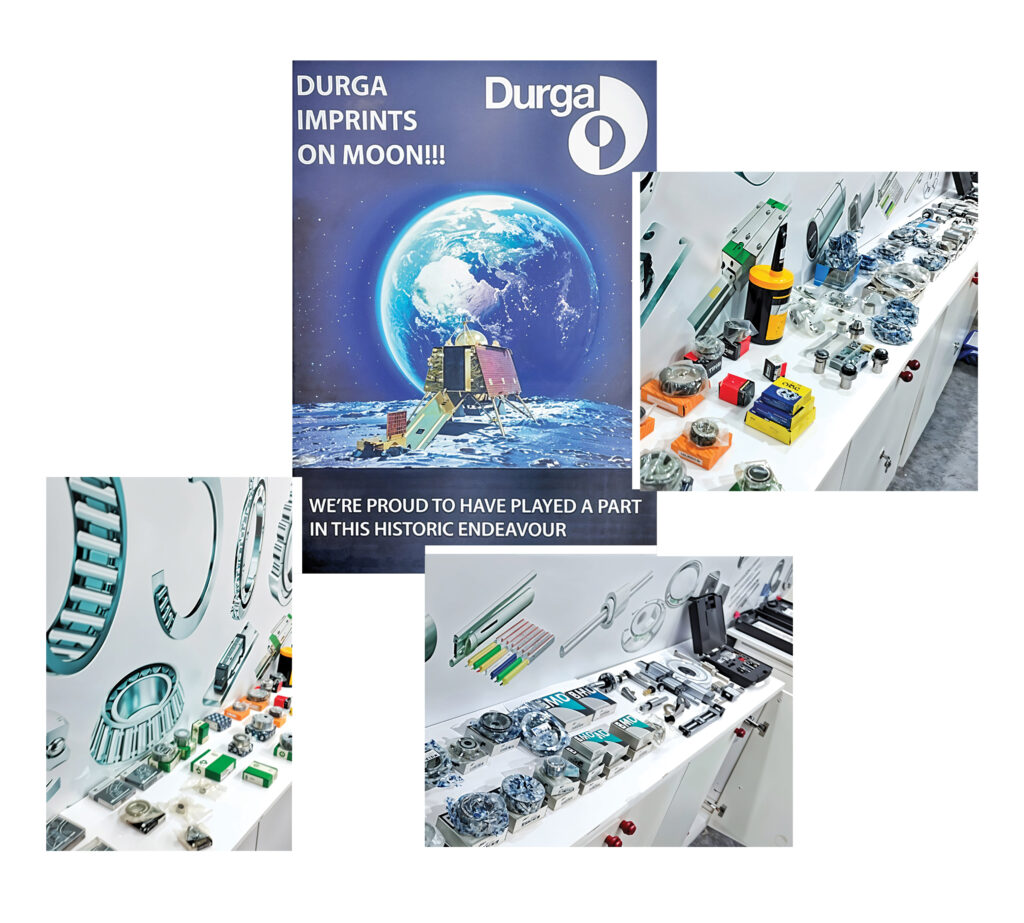

Speaking to The Voices, a representative from Durga Bearings, a company, stated that it supplies precision bearings to various Indian manufacturers. He claimed that the Indian Space Research Organisation was among the coveted buyers from the company. The company also proudly displayed its involvement in the ISRO’s Chandrayaan project, a part of the moon landing.

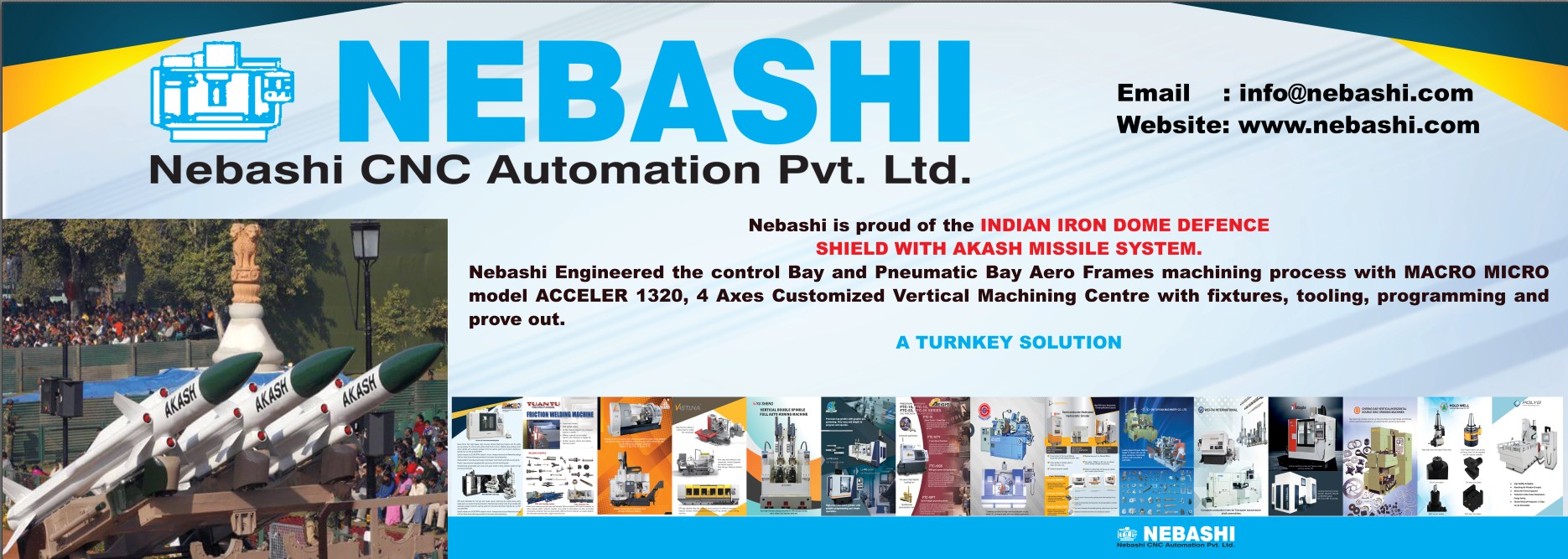

Whitchurch Nelson from Nebashi CNC Automation Pvt. Ltd., a Taiwan-based company, speaking with The Voices, stated that his organisation manufactures precision machinery designed to produce high-quality end products. His company has been collaborating with the Indian government’s defence-related companies, including Hindustan Aeronautics Ltd., Defence Research and Development Organisation, Bharat Electronics Ltd., Gas Turbine Research Establishment, and Bharat Heavy Engineering Ltd., among others. These machines were used for the development of the Akash Missile System- an indigenous medium-range surface-to-air missile.

Kamal, a member of the AIMEA management committee for ACMEE 2025, stated that the event served as an indicator of India’s rapid industrial transformation. Foreign joint ventures and wholly owned subsidiaries are deepening their footprint in India, bringing technology transfer, smart manufacturing, supply chain localisation and reliability under one roof, making India one of the global manufacturing hubs, he said.

Robotics, Automation and Smart manufacturing demo in action

The integration of Indian MSMEs (Micro, Small, and Medium Enterprises) with global giants on the show floor reflected the manufacturing ecosystem which India is building in sync with the global stage. This is also aimed at promoting the local ambition. Here are some amazing examples of how robotics is being adopted across the manufacturing sector in India. Japanese manufacturer Mitutoyo South Asian Private Limited showcased robotics and automation manufacturing in the automotive sector.

The stall of Japanese manufacturer Mitutoyo South Asia Private Limited

Santhanakrishnan, a member of the AIMEA management committee, speaking to The Voices, stated that ACMEE has brought together the machinery, components, and financial institutions for the manufacturing sector, while also promoting various government schemes as part of the Make in India Initiative.

Various conferences were held to promote, understand, and support India’s industrialisation, featuring workshops and discussion panels focused on the future workforce. These highlighted the need for digitally literate machinists, automation engineers, and AI-integrated designers. Nelson was of the opinion that the Indian government was very responsive and helpful.

ACMEE 2025 highlighted the fast pace at which India’s manufacturing capability is evolving. Srinivas from AIMEA stated that India could be the most cost-effective production hub in the supply chain. The country has also emerged as a reliable partner. From high-precision tools to AI and cloud-integrated machines, it was more than just an expo. It gave a vision of how India plans to build, create, assist and lead the world in the decades to come.

Copy Editor: Harshita Agrawal